As scheelite, as the main mineral currently used for the development and utilization of tungsten resources, the exploration of efficient mineral processing methods has always attracted much attention. With the gradual depletion of wolframite resources, how to better extract high-grade tungsten resources from scheelite has become an important issue in the mining field. This article will provide an in-depth introduction to the two main beneficiation methods of scheelite, gravity separation and flotation.

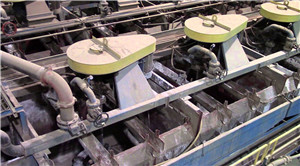

Gravity separation is a method that utilizes the density difference between minerals for mineral processing. For coarse-grained scheelite, its density is much greater than quartz, feldspar and other gangue minerals, so the gravity separation method has become the preferred process. In actual operation, the mineral processing plant will use equipment such as spiral chutes, shaking tables, and centrifugal concentrators to achieve effective recovery of scheelite.

It is worth noting that scheelite is brittle and easily muddy during the grinding process. In order to avoid this phenomenon, the mineral processing plant should try to use coarser grinding particle size for recycling under the conditions of basic monomer dissociation. In addition, process measures such as segmented crushing and screening, grinding classification and separation can also help improve the recovery rate of scheelite.

The flotation method is a method of beneficiation that utilizes the differences in physical and chemical properties of mineral surfaces. For the recovery of fine-grained scheelite and fine mud, flotation has significant advantages. According to different process conditions, scheelite flotation can be divided into two types: heated flotation and normal temperature flotation.

Heated flotation: In this process, the slurry is first roughed at room temperature. After the scheelite coarse concentrate is concentrated, a large amount of water glass is added under high temperature conditions for stirring. After a long period of stirring and analysis, the gangue minerals are inhibited, while the scheelite remains hydrophobic and floatable. Finally, the slurry is diluted and concentrated at room temperature to obtain high-grade scheelite concentrate.

Normal temperature flotation: Different from heated flotation, the roughing and selection stages of normal temperature flotation are carried out at normal temperature. The key to this process is to strengthen the selective suppression of gangue minerals during roughing operations, thereby increasing the enrichment ratio of scheelite. Commonly used inhibition methods include using mixed inhibitors (such as lime + sodium carbonate), high-efficiency collectors (such as CF collector), and using different water glass moduli to produce different inhibitory effects on gangue minerals.

In short, the beneficiation process of scheelite needs to be reasonably selected based on the characteristics of the ore. In actual production, the mineral processing plant should fully consider the ore's mineralization conditions, mineral composition and other factors to formulate a practical mineral processing plan. By continuously optimizing and improving the mineral processing process, we are expected to improve the resource utilization rate of scheelite and contribute to the sustainable development of tungsten resources.

© 2021 Yantai KZ Mining Processing Technology & Equipment Inc.