Vanadium titanium magnetite is an important mineral resource with high economic value. Optimizing its mineral processing process and improving mineral processing efficiency are of great significance for making full use of vanadium titanium magnetite resources and improving economic benefits.

The vanadium-titanium magnetite beneficiation process mainly uses two methods: magnetic separation and flotation. Magnetic separation mainly uses the strong magnetic properties of vanadium-titanium magnetite to separate it from non-magnetic minerals; flotation uses the differences in hydrophobicity and hydrophilicity on the surfaces of different minerals to separate different minerals.

Crusher: used to break large pieces of vanadium titanium magnetite into small pieces for subsequent processing.

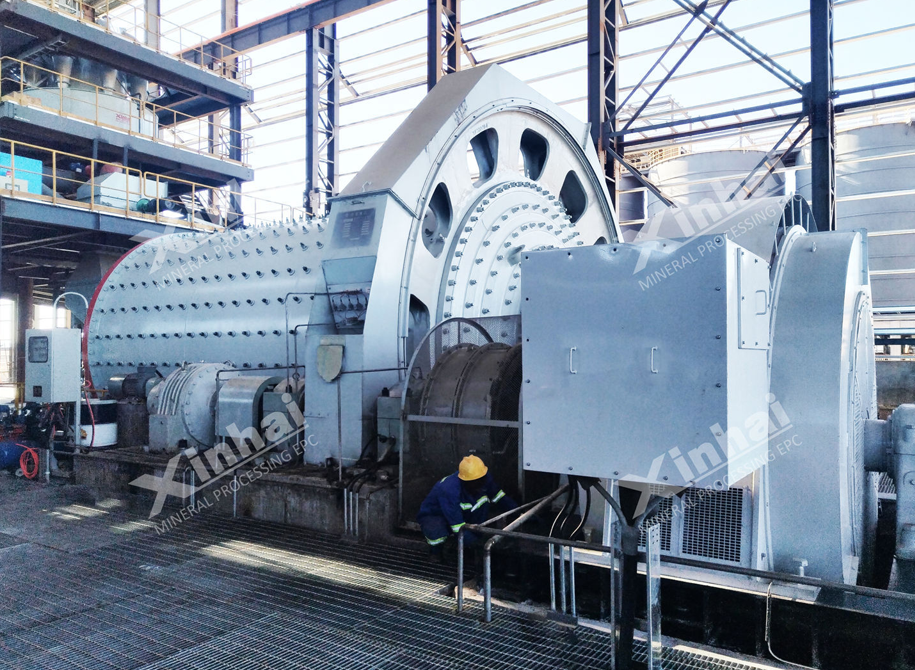

Ore grinding machine: further refine the crushed ore to improve the efficiency of mineral processing.

Flotation machine: used to separate vanadium titanium magnetite from other minerals.

Magnetic separator: used to separate vanadium titanium magnetite from other non-magnetic minerals.

Chemical agents: used to adjust the hydrophobicity and hydrophilicity of mineral surfaces and improve mineral processing efficiency.

Ore crushing: First, large pieces of vanadium-titanium magnetite are crushed, generally to a particle size of 10-30mm.

Ore grinding: further refine the crushed ore to meet the requirements of mineral processing.

Flotation: During the flotation process, flotation agents are added to the slurry to promote the combination of vanadium titanium magnetite and foam and float. Common flotation agents include acetone and yellow syrup.

Magnetic separation: The flotation products are magnetically separated to remove ferromagnetic impurities.

Chemical selection: Use chemicals to oxidize the product to remove harmful impurities and obtain high-purity titanium dioxide, high-purity vanadium oxide, etc.

Product processing: The obtained titanium dioxide, vanadium oxide and other products are further processed, such as washing, drying, etc.

Reasonable selection of process parameters based on ore properties and equipment conditions to improve mineral processing efficiency.

Strictly control the grinding fineness and the amount of flotation agent to ensure the best mineral processing effect.

According to the characteristics of different ores, select appropriate chemicals, adjust their dosage and action time, and improve the oxidation effect and product purity.

Strengthen equipment maintenance and overhaul to ensure normal operation of equipment and improve production efficiency.

Pay attention to environmental protection and comprehensive utilization of resources, reduce waste emissions, and improve resource utilization.

In short, the vanadium-titanium magnetite beneficiation process needs to be comprehensively considered and optimized based on the ore properties, equipment conditions and production requirements. In actual operations, attention should be paid to improving mineral processing efficiency, reducing production costs, strengthening environmental protection and comprehensive utilization of resources, and achieving dual improvements in economic and social benefits.

© 2021 Yantai KZ Mining Processing Technology & Equipment Inc.