Nickel ore resources are mainly based on sulfide nickel ore and laterite nickel ore, and after nearly a hundred years of mining, nickel sulfide ore resources have been gradually exhausted. Due to the depletion trend of nickel sulfide ore, the world has not started new production capacity of pure nickel using nickel sulfide ore in the past 10 years.

In order to meet the demand for nickel in world economic development, especially new energy materials, people have to turn their attention to laterite nickel ore with rich nickel resources.

However, laterite nickel ore has completely different properties than nickel sulfide ore. Nickel sulfide ore is generally of high grade. Sulfide ore with a nickel content of more than 3% can be directly smelted in the furnace, and nickel-rich or nickel-poor ore with a nickel content of less than 3% can be enriched by beneficiation. The laterite nickel ore has a low grade and taste, and the nickel content is generally 1% to 2%. The content of impurities such as iron, magnesium and aluminum often reaches more than 50%, and the total content of impurities is often more than 30 times the nickel content. The method effectively carries out the enrichment of nickel. In order to win the hard bone of laterite nickel ore, it is necessary to face hard technology and overcome the problem of efficient utilization of low-grade nickel ore.

The development of laterite nickel ore has a pyro process route and a wet process route. The current international popular pyro smelting is to directly smelt more than 40% of the iron in laterite nickel ore with nickel into nickel-iron alloy. Nickel-iron alloy is a high-quality and cheap masterbatch for stainless steel. Iron is a useful element of stainless steel and does not need to be separated. However, in battery materials, iron is a harmful element. Iron and nickel cannot be used together and must be separated. Therefore, , The treatment of laterite nickel ore is how to effectively extract nickel with a content of about 1.5% from impurities with a content of up to 50%, which cannot be completed by the current pyrometallurgical technology. The cases of wet smelting of laterite nickel ore in operation around the world prove that the difficulty of hydro smelting is that other elements such as iron, magnesium and other elements coexisting with nickel are also dissolved together with the dissolution of nickel, which requires a large amount of acid consumption, and then needs to be recycled. Separation greatly increases the unit metal smelting cost and even loses the economy.

GEM is one of the representative enterprises in the recycling of waste resources in the world and one of the largest nickel resource recycling companies in the world. It has conquered the key technologies of recycling and utilization of scarce resources such as cobalt and nickel, and recycled cobalt and nickel materials to replace mainstream products. More than 10,000 tons of nickel resources are recovered from nickel waste, accounting for 8% of China's nickel resources mining.

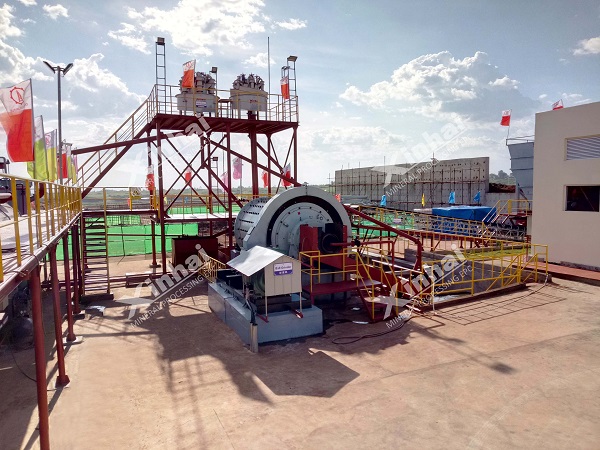

A high-level team led by doctors and experts from GEM has built an engineering laboratory for efficient utilization of laterite nickel ore in Indonesia within two months. It has conducted a large number of tests on the typical laterite nickel ore in the project location, mastered the characteristics of minerals, and innovatively developed the medium. The process and equipment for low-pressure treatment of laterite nickel ore adopts methods such as enhanced pressure and high-acid conversion to reduce acid consumption and thus reduce costs. After scientific verification, the process route of pressure acid leaching - nickel cobalt hydroxide precipitation - production of battery-grade nickel sulfate has been formed, which greatly reduces investment costs, production costs, and construction period, and realizes the economical and efficient smelting of laterite nickel ore. Efficiency, the establishment of the world's advanced laterite nickel ore directly produces a new industrial model of nickel chemicals for new energy, which is of great significance to the efficient use of global low-grade nickel resources.

© 2021 Yantai KZ Mining Processing Technology & Equipment Inc.