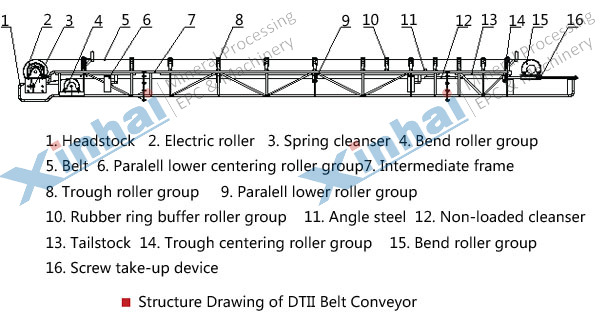

Belt Conveyor is mainly composed of two end rollers and the closed belt which is tightly set on it. The one driving the conveyor belt is named the driving roller; the other one only used for changing the motion direction of the conveyor belt is named the bending roller. The driving roller is driven by the motor through the reducer while the conveyor belt is dragged by the friction between the driving roller and the conveyor belt. The driving roller is generally installed on the discharging side to increase the traction and convenience of a drug. Materials are fed by the feeding end, dropped on the conveyor belt, and discharged by the discharging end which is driven by the conveyor belt friction.

| Belt Width B (mm) | |||||||

| Carrying Idler Type | Belt Speed (m/s) | 500 | 650 | 800 | 1000 | 1200 | 1400 |

| Trough Idler | Conveying Capacity Q (t/h) | ||||||

| 0.8 | 78 | 131 | — | — | — | — | |

| 1.00 | 97 | 164 | 278 | 435 | 655 | 891 | |

| 1.25 | 122 | 206 | 348 | 544 | 819 | 1115 | |

| 1.6 | 156 | 264 | 445 | 696 | 1048 | 1427 | |

| 2.0 | 191 | 323 | 546 | 853 | 1284 | 1748 | |

| 2.5 | 232 | 391 | 661 | 1033 | 1556 | 2118 | |

| 3.15 | 824 | 1233 | 1858 | 2528 | |||

| 4.0 | 2202 | 2995 | |||||

© 2021 Yantai KZ Mining Processing Technology & Equipment Inc.